Blakefield Mine - Xtrata

CASE STUDY

Client

Xtrata

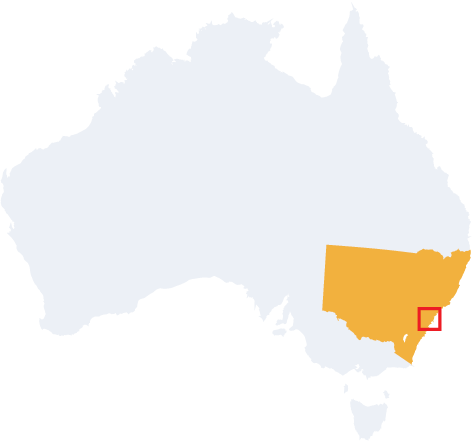

Location

Blakefield Mine

Year

2012

Objective

Design and delivery of fly ash injection to entomb UG fire site and build UG seals in UG roadways to control ventilation movement in an inert atmosphere. Tim injected a total of 4,872t of fly ash to build seals which were pressure tested between to prove a seal was obtained. The fly ash was injected using nitrogen to prevent oxygen ingress into the inertised coal mine.

Scope

The scope was design, supply, and deliver including all risk assessments and safe work instructions to achieve this project successfully. Some flyash was injected as a wet grout onto fire site, whereas most was used to build seals to isolate the fire site.

Result

The flyash seals were proven to hold 2500Pa, and enabled underground reentry access to working to continue mining away from the burned long wall area.