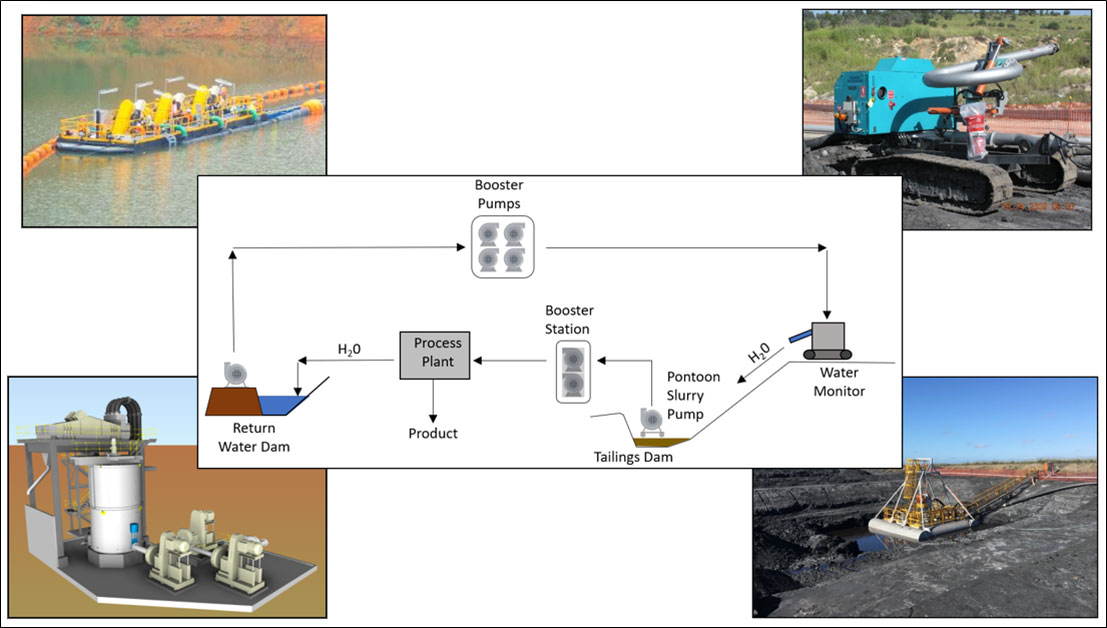

DFS delivery as Hydraulic Mining content expert. Proposed Hydraulic Mining solution included:

- Water supplied to 4 x HP pumps at approx. 1,200m3/hour

- HP pumps deliver water to 4 x monitors (2 x spare) at 25bar. Each monitor mining 500t/hr

- Mined tailings slurry flows down trench to 4 x pontoon VSPs and is pumped to a trash screen & surge tanks

- Screened slurry is pumped via 3 x slurry pumps 5km to process

GEM Projects specialises in Hydraulic Mining techniques, providing a process that ensures:

- Improved resource utilisation

- Re-use of tailings storage facilities

- Safety, cost and environmental advantages over other methodologies

- Minimal interaction with operations

- Telemetry to monitor tonnages and densities

- Consistent production tonnage and density to client specification

Proven Commodities reclaimed by Hydraulic Mining include:

- Gold – bulk density of 1.63t/m3, particle SG ~2.71t/m3, with sizing P80 @ av. 80µm

- Coal – dry bulk density of 1.5t/m3 with av. sizing of 20-40µm, 30% w/w solids

- Zn/Pb – dry bulk density 1.9t/m3, particle SG 2.8t/m3, P60 45µm, 40-50% w/w solids

- Magnetite – South Africa hydraulically mine magnetite tailings with particle SG of 4.6t/m3 – SG the key when tailing >150µm to avoid pipe blockage.